Immersion Cooling

The Two-Phase Liquid Solution You’ve Been Waiting For

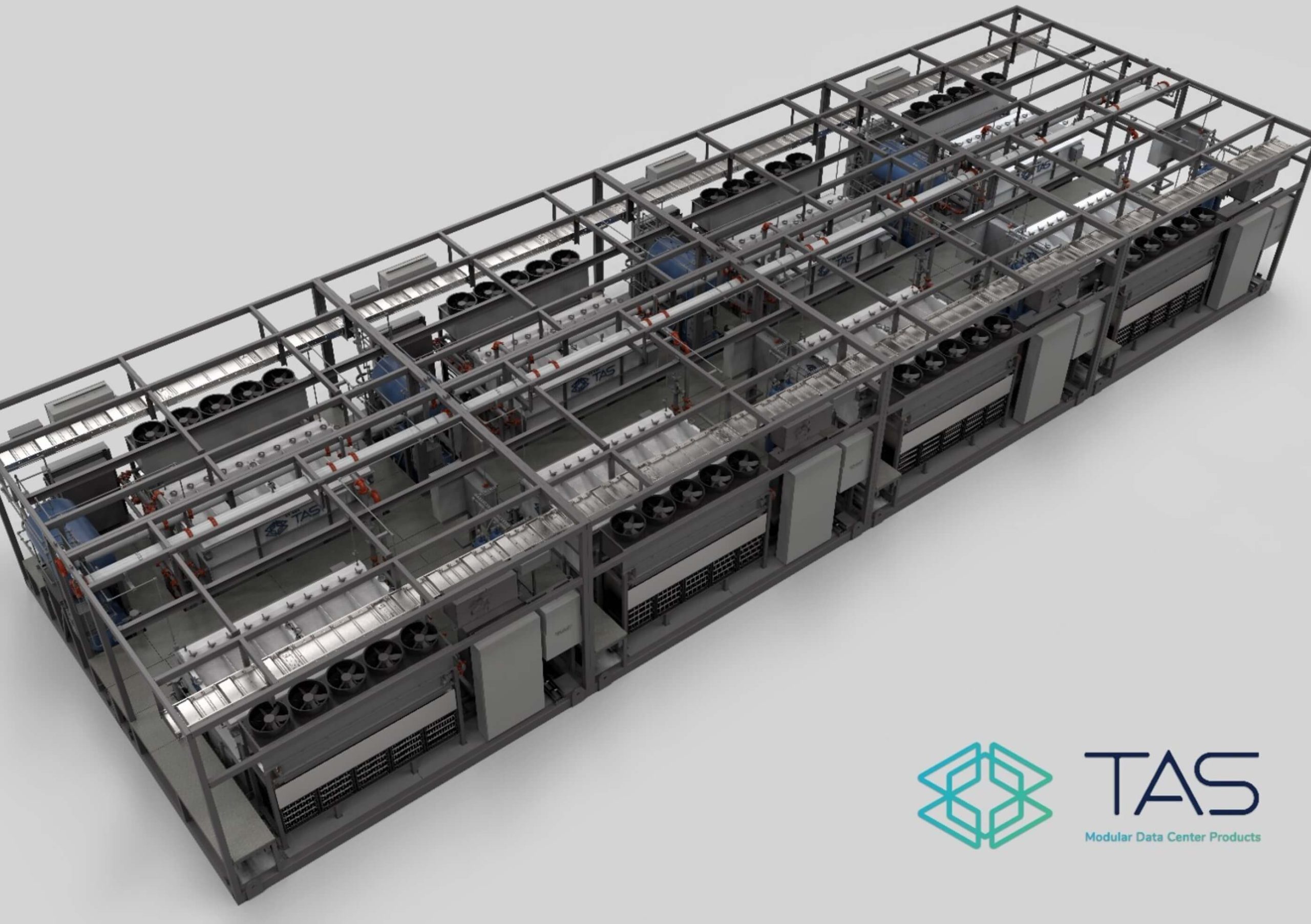

The constant evolution of data technology brings many exciting things. Data Centers have become more compact and faster than ever. “The bigger, the better” is a phrase of the past, as previous generations of IT hardware are phased out for sharper and more sophisticated models. Keeping up with the demand of the information society is no easy feat, and like many things, even the newest technology can get burnt out. Ensuring your ROI in the world of IT is a must, and we have the solution that you never knew you needed — Two-Phase Liquid Immersion Cooling. Learn how TAS has cornered this market and how we think you could benefit most.

What is Liquid Immersion Cooling?

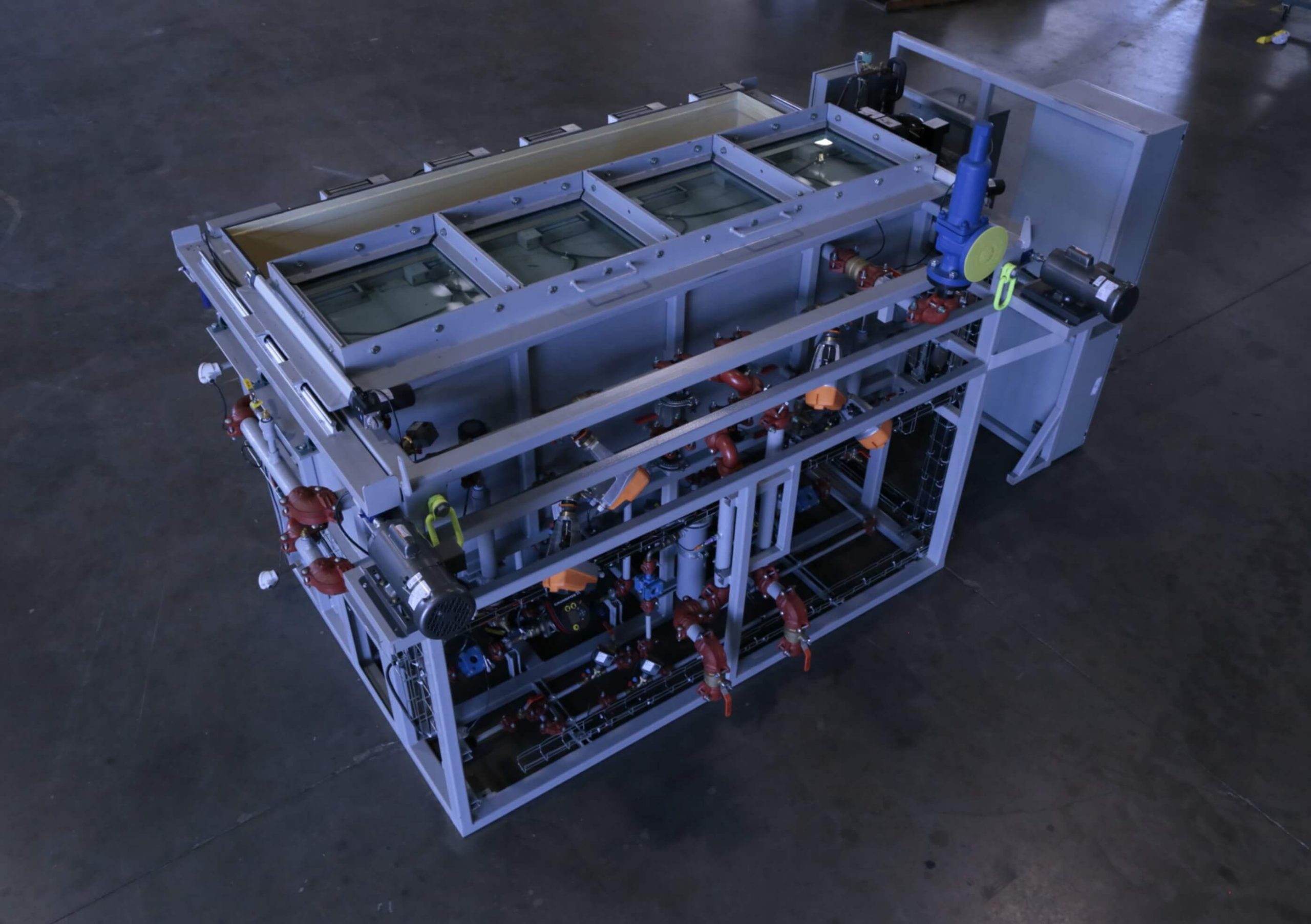

Liquid Immersion Cooling is the process of fully submerging data center technology into dielectric fluid, causing the gradual and sustainable cooling of overheated materials. As opposed to air or water cooling, liquid immersion cooling is an eco–friendly, self-sustainable technique that requires no human input or additional energy consumption. The closed containment of 50-degree Celsius dielectric fluid allows the heat of the data center to circulate throughout the body of the cooling system, which then goes into cooling pumps and is circulated continuously until the complete cooling of the data center technology.

What Types of Liquid Immersion Cooling are There?

There are two techniques to consider when deciding which Immersion Cooling process is best for your electronic components — Single Phase and Two-Phase Immersion Cooling. Both Immersion cooling techniques require dielectric fluid, which is a non-conductive solution that effectively absorbs heat and can reach an extremely high boiling point. Both techniques are efficient at insulating, cost-effective, and environmentally friendly. Here’s how you can decipher which option is best for your needs.

Single Phase Immersion Cooling

During Single Phase Immersion Cooling, once the data center technology is fully emerged in the dielectric fluid and enclosed within the cooling system tank, the heat from the submerged technology is transferred into the fluid and circulated through cooling pumps. Lowering the temperature of the fluid using air pressure, the pumps are able to push out newly cooled dielectric fluid back into the main tank. Repeating this process will cause the gradual cooling of the data center technology in a way that uses no additional points of energy, human contact, or toxic chemicals.

Two-Phase Immersion Cooling

During Two-Phase Immersion Cooling, the initial step of fully emerging the data center technology into the dielectric fluid is the exact same as the Single Phase Immersion technique. However, during the Two-Phase technique, the beginning temperature of the dielectric fluid is exponentially higher because the fluid has been boiled and condensed in order to reach a point of greater transferable capabilities. When the heat from the data center meets the condensed dielectric fluid, vapor begins to form, rises, and is then transferred outside of the tank.

Power and Energy Efficient

Unlike other companies, TAS specializes in quality, speed, and customization. We’ve been a leader in the production of modular solutions and we know first-hand how crucial it is that your data technology is running efficiently. We’ve had the privilege of providing our clients with a new “hands-off” approach to data center repair and construction that saves them time and money. Here at TAS, we prefabricate our modular builds to your exact needs offsite and assemble them onsite for you. This process is 40% quicker than going the traditional route of on-site builds and substantially reduces the risk of schedule delay. Our clients save money across the board and we are proud to consistently achieve success through our quality network of engineers and partners in the data center arena. You can count on all TAS solutions to be modular, reliable and efficient – with fast delivery and installation.

The Benefits of Liquid Immersion Cooling

Revolutionary data centers and IT are invaluable. With more people working from home than ever, functioning in today’s society without their use would be nearly impossible. Keeping up with the everyday needs of people and businesses alike can result in overutilization, which then spirals into lagging and subsequently overheating. Power consumption is expected to increase by 10x in comparison to what we consume in the present day, and unfortunately, traditional forms of cooling are simply no match for our needs.

Benefits of Immersion Cooling

- Improved performance and continuous junction cooling

- Dielectric fluid allows for an environmentally friendly and non flammable solution

- Elimination of specialty tradesmen for installation and specialty parts

- More service space availability due to the minimal footprint used

Features of Immersion Cooling:

- Unmatched IT density (> 10x air)

- Turbo/Overclock IT (>up to 30%)

- Ultra low PUE (< 1.08)

- Can be fully integrated with the facility, Density of 5000+ Watts per RU

Why Immersion Cooling is Better

Traditional forms of cooling include water and air. Air, one of the original forms of cooling, functions by blowing chilled air directly onto overheated data centers in order to cool them down. Overall, the process can take a long period of time, and depending on if there is an imbalance of overheated parts in the data center it may not be effective for cooling at all. Water cooling is similar to air cooling in that the water is concentrated in a certain area and moves in one direction in order to absorb the heat and push it through and out of the data center. Water cooling has a number of factors that can contribute to the success or failure of cooling, but one of the main obstacles is that leaking happens all too often and the combination of water and electricity never ends well. Maintaining temperature control is key in this equation, hence why Immersion Cooling into a non-conductive solution trumps in every scenario. Getting ahead of the occasional mishap will allow for fewer schedule delays or lags in production. TAS provides this and the ability to customize solutions in the form of a module that fits your exact specifications.

Solidify your ROI

Creating the ideal work environment is crucial to business owners, property owners, and technology workers alike. Investing time and money into data centers is no small feat, and TAS is dedicated to providing turnkey solutions that are efficient, cost-effective, and personalized specifically for your needs. Our modular cooling units feature ultra-low PUE (< 1.08), an unmatched IT density, and are fully integrated into your system for continued use and benefit. Contact us to experience firsthand how exclusive our services, team, and products are.